PROJECTS

PDF Combination CO-Smoke Detector

System Overview

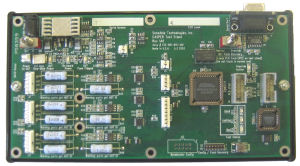

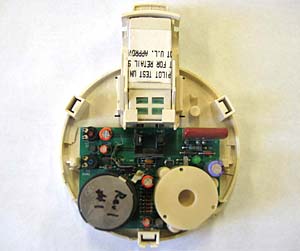

Bolton Engineering worked with FirstAlert purchasing agents to review the parts used in their existing products to see what parts could be used in the new design. Through careful selection, Bolton Engineering was able to take over 80% of the parts for the new design from other FirstAlert products. Bolton Engineering evaluated several design concepts and wrote both test and production firmware. During debug, Bolton Engineering included a software UART in the code to allow product status to be sent serially out the only spare microcomputer I/O line to a data logging computer. By placing the two trim pots in the same board location as on a previous CO detector design, Bolton Engineering was able to have the new product be automatically trimmed in production using the same FirstAlert production line CO detector test and trim equipment that was used for a previous design

Project Scope

Bolton Engineering worked with the client to write a specification, designed the schematics, designed the single-layer board (with jumpers), modified existing FirstAlert firmware to implement the smoke detector and interconnect functionality, debugged the system, and delivered a dozen working prototypes. Millions of detectors were produced over the design lifetime.

FirstAlert had developed a variety of Smoke Detectors and CO Detectors, and was interested in quickly developing a combination product. In order to save time to market, the product had to use parts that were easily available and had to fit into an existing CO Detector case with minimal tooling changes. Recent product introductions by competitors meant that FirstAlert was especially concerned about cost.