PROJECTS

PDF Brushless DC Motor Driver Retrofit

System Overview

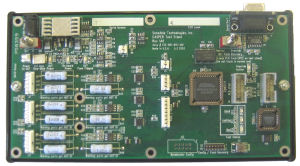

Bolton Engineering worked with the client to create a small add-in board that emulated the functionality of the original part. The design was complicated by there not being any integrated circuits that could perform the exact functions of the original chip. Several chips were required, and there was little space. The original client circuit board design was done in 2-layers and had significant ground noise. Several design iterations were required to work around these issues and get the design working perfectly

Project Scope

Bolton Engineering designed the schematics and circuit board, fabricated and debugged the hardware, and delivered ten prototypes. The work was done over an extremely aggressive schedule.

The client had been producing the Hemostatis Testing System for over ten years. It had acquired the product line from another firm and did not have in-house design staff to make changes to the design. The client had known that the brushless 3-Phase DC motor drive integrated circuit (UC3620) was no longer produced, but had been reluctant to make changes to the design as they were planning to replace the product with a completely new design. They were manufacturing a new run of equipment, but had run into difficulties finding chips. Production was stopped until the design could be patched to run with different brushless DC motor drivers.